Search This Supplers Products:Kitchen AppliancesGas Water HeatersGas HobsGas StovesGas GeysersWATER HEATER PARTS

C.K.D Components gas cooker burner bottom Cold rolled or galvanized sheet

- group name

- Gas cooker components

- Min Order

- 1 piece

- brand name

- WOMADE

- Nearest port for product export

- Shunde

- Delivery clauses under the trade mode

- FOB

- Acceptable payment methods

- T/T, L/C, Cash

- update time

- Thu, 29 Aug 2019 16:19:58 GMT

Packging & Delivery

-

Min Order1 piece

Briefing

Material available galvanized sheet or cold rolled sheet, strong thickness, long life time

Detailed

PRODUCT SPECIFICATION

Main Specification | |

|

Type

|

gas hob bottom

|

|

Panel material

|

Cold rolled sheet/Galvanized sheet

|

|

Thinkness

|

0.6mm / 0.7mm

|

|

Finishing

|

Gray/Black coating

|

PRODUCT FEATURE

Bottom of gas stove gas cooker gas hob ,Gray/Black coating

Available single burner/two burner/three burner/ four burner/five burner/ six burner

Material available galvanized sheet or cold rolled sheet

Strong thickness, long life time

Panel OEM/ODM customized size and design

Well seaworthy packing

Fast delivery

PACKAGING

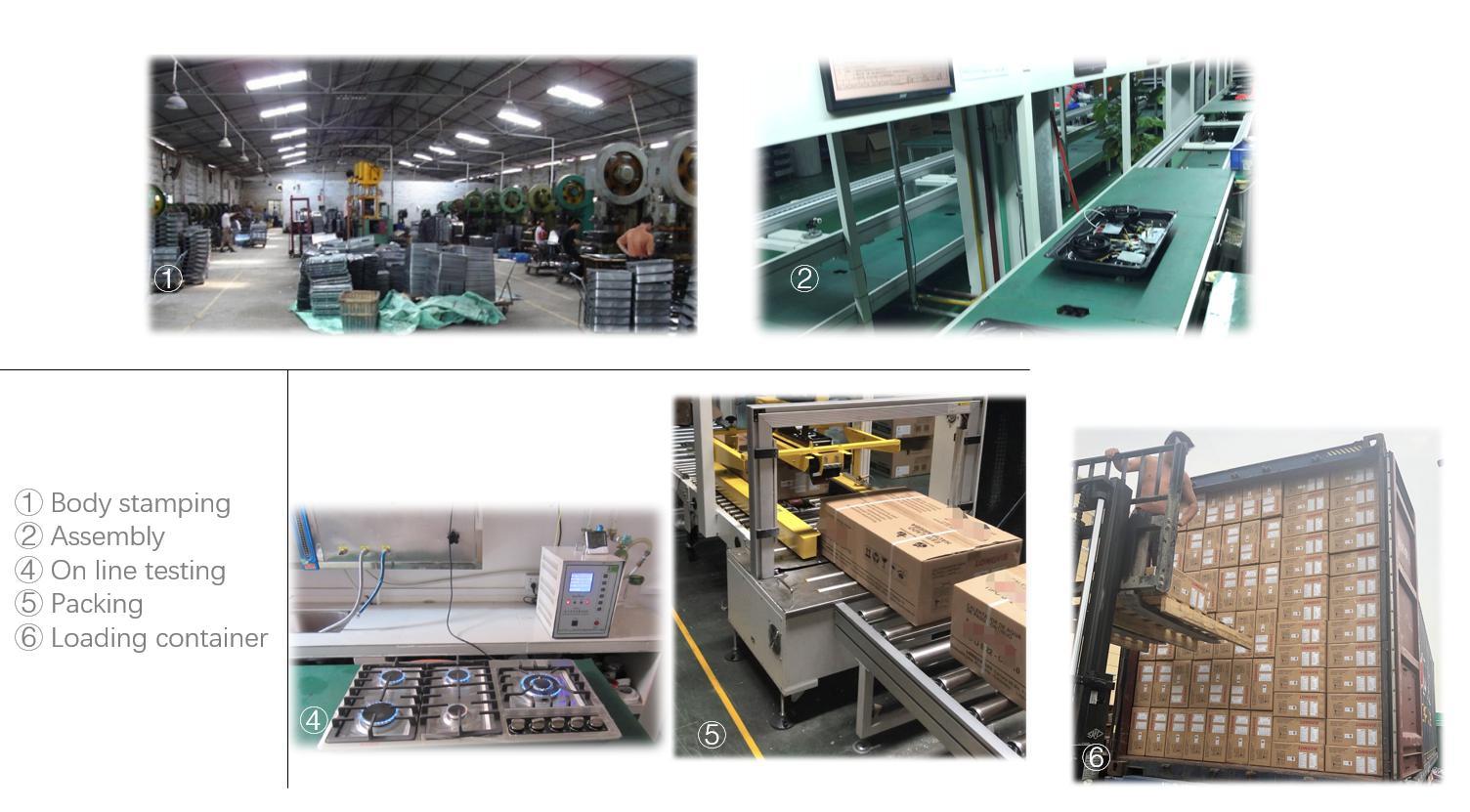

PRODUCTION PROCESS

gas hobs/gas cooker/ build-in hobs manufacture production process

1. Body stamping (make for panel and bottom components);

2. Panel silk-screen( print customers logo and operation instruction);

3. Assembly gas hob on assembly line (assemble all components to be completed unit);

4. On line test (Performance test for the build-in hob, appearance inspection for the gas hob);

5. Packing (Pack the completed unit of gas hob with polyfoam, polybag and accessories in strong carton box or color box)

6.Loading container ( Load the gas hob and spare parts in 20ft or 40hq container)